Milwaukee 6390 User Manual Page 1

Browse online or download User Manual for Circular saws Milwaukee 6390. SERVICE PARTS LIST - Milwaukee Electric Tool

- Page / 2

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

1 02-04-0847 Ball Bearing (1)

2 02-04-1850 Ball Bearing (1)

3 02-50-2423 Needle Bearing (1)

4 05-78-0130 Switch Screw (4)

5 45-22-0605 Lower Guard Sleeve (1)

6 06-75-0035 5/16-18 x 9/16" Blade Screw (1)

7 06-75-5850 5/16 -18 L.H. Thread Bolt (1)

8 06-75-5860 1/4-20 x 3/4" Hex Hd. Screw (1)

9 06-82-5314 10-24 x 1/2" Pan Hd. Taptite T-25 (11)

10 06-82-5358 12-24 x 3/4" Pan Hd. Taptite T-27 (3)

11 06-82-5474 10-24 x 1-3/4" Pan Hd. Taptite T-25 (1)

12 06-82-7270 8-16 x 5/8" Pan Hd. Slt. Plastite T-20 (10)

13 06-82-7395 8-16 x 1-3/4" Pan Hd. Plastite T-20 (2)

14 05-88-0305 K50 x 16mm Delta PT Screw (3)

15 06-82-0090 10-14 x .562 Plastite T-25 Screw (2)

16 06-95-6290 M5 x 2.24 x 18 PH (PT) Screw (1)

18 12-20-6390 Service Nameplate Kit (1)

19 16-70-0056 Armature Assembly (1)

20 18-70-0046 Field (1)

21 22-18-1075 Brush Assembly (2)

22 22-22-1030 Brush Tube Assembly (2)

23 22-64-0100 Cord Assembly (1)

24 23-66-2118 Switch (1)

27 25-20-0120 Upper Guard Cover (1)

28 14-67-0256 Bevel Bracket Assembly (1)

29 28-14-0100 Gearcase (1)

30 28-41-1032 Lower Guard Kit (1)

31 31-05-0045 Baffl e (1)

32 31-15-0465 Motor Cover (1)

33 31-44-0055 Right Handle Half (1)

34 31-44-0060 Front Handle (1)

35 31-44-0075 Left Handle Half (1)

36 31-44-2156 Handle Lever (1)

37 31-50-2225 Motor Housing Assembly (1)

38 31-52-0015 Depth Lever (1)

39 31-52-0025 Guard Lever (1)

40 32-75-3205 Gear (1)

41 34-40-1375 O-Ring (1)

42 34-40-1380 O-Ring (1)

43 34-60-0320 External Retaining Ring (1)

44 34-60-2330 Klip Ring (1)

45 38-50-0060 Spindle (1)

46 40-50-0045 Guard Spring (1)

47 40-50-0055 Compression Spring (1)

48 40-50-8041 Spring (1)

49 42-16-0160 Handle Band (1)

50 42-38-0222 Rubber Bumper (1)

51 42-42-0275 Spindle Lock Button (1)

52 43-34-0790 Inner Flange (1)

53 43-34-0795 Outer Flange (1)

54 43-78-0155 Hub (With Bearing) (1)

55 44-10-0130 Bevel Adjustment Lever (1)

56 44-20-0510 Spindle Lock Pin (1)

57 44-40-0780 Adjustment Nut (1)

59 44-60-0075 Thru Pin (1)

60 44-60-0085 Tapped Pin (1)

61 44-60-1180 Pivot Pin (1)

62 44-66-0065 Retaining Plate (1)

64 44-66-0200 Lock Plate (1)

65 44-72-0050 Pointer (1)

66 45-04-0485 Bumper Screw (1)

68 45-08-0416 Depth Shaft (1)

54-40-6004

Dec. 2009

54-40-6003

58-01-1321

983E

6390-20

7-1/4" CIRCULAR SAW with TILT-LOK

®

HANDLE

REVISED BULLETIN

SERVICE PARTS LIST

BULLETIN NO.

WIRING INSTRUCTION

DATE

SPECIFY CATALOG NO. AND SERIAL NO. WHEN ORDERING PARTS

CATALOG NO.

SERIAL

NUMBER

MILWAUKEE ELECTRIC TOOL CORPORATION

13135 W. LISBON RD., BROOKFIELD, WI 53005

Drwg. 1

FIG. PART NO. DESCRIPTION OF PART NO. REQ.

69 45-16-0160 Shoe Assembly (1)

70 45-88-0577 Wave Spring Washer (2)

71 45-88-8461 Washer (1)

72 45-88-8460 5/16" Washer (1)

74 49-96-0345 Blade Wrench (Not Shown) (1)

75 -------------- Fan (1)

EXAMPLE:

Component Parts (Small #) Are Included

When Ordering The Assembly (Large #).

00

0

FIG. NOTE

1 Orient the ball bearing so that the seal faces the commutator.

3,29 Orient the needle bearing such that the text is facing the

gear. Press the bearing .015" subfl ush to the gear cavity

wall.

11 Tighten the handle lever screw such that it requires 3-7 lbs.

force to close the handle lever to the locked position.

29 Apply .320 - .360 oz. "Y" Grease, No. 49-08-5270,

to gear bore of upper guard gearcase. The grease should

be directed toward the pinion end of the armature.

= Part number change from

previous service parts list.

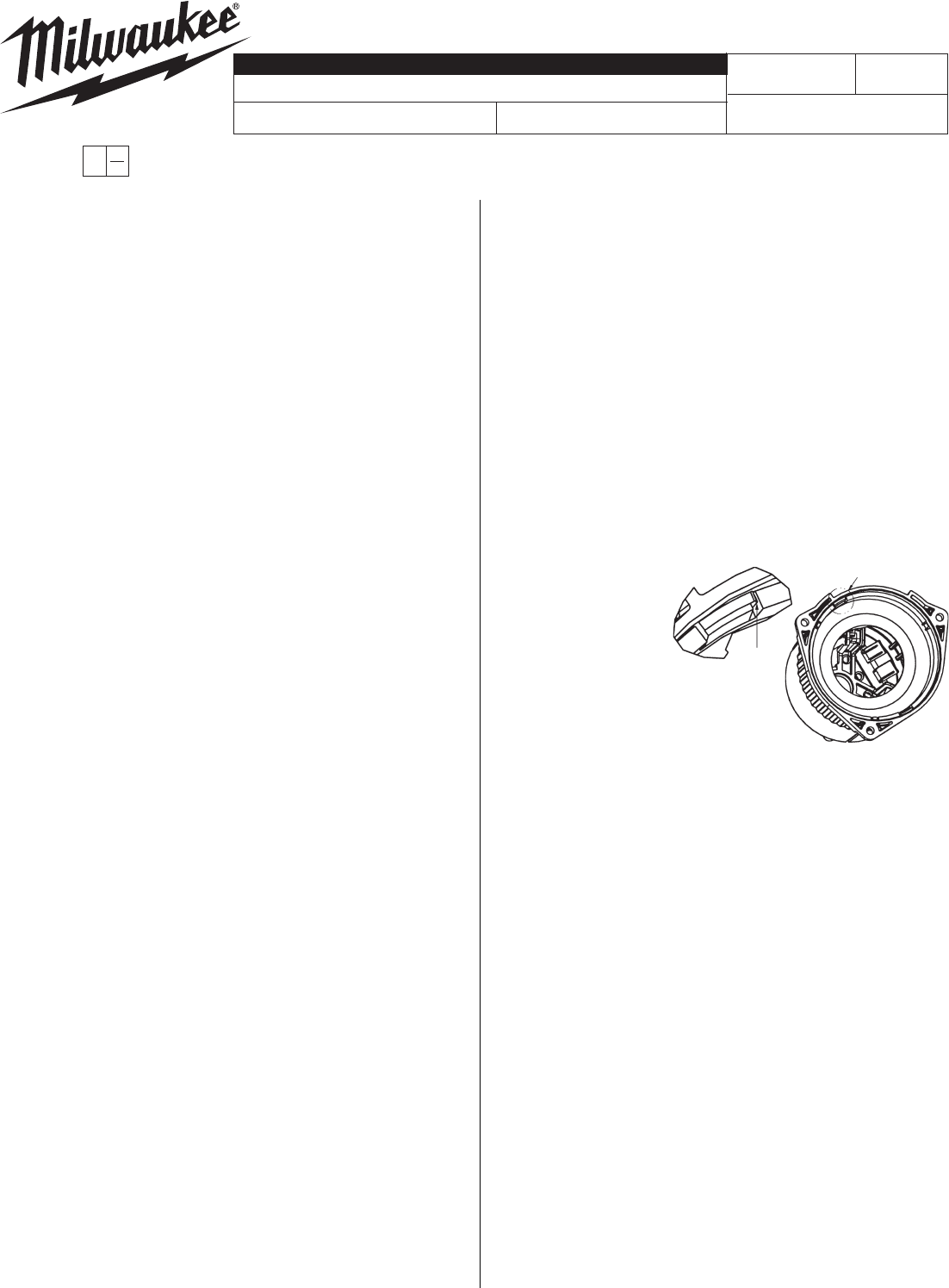

29,31 Orient the baffl e

with the crush

ribs aligned

with the screw

holes in the motor

housing and the

locator tabs aligned

and seated

as shown.

30 Functionally check the lower guard with the saw set at full

depth of cut and zero degree bevel. Place the saw upside

down with the shoe horizontal. Retract the lower guard

100%. Release the lower guard lever. The guard should

return in a brisk manner.

38 When tight, the depth adjustment lever should be parallel

( ±20°) with the shoe.

43 Orient the external retaining ring such that the beveled face

is towards the guard.

55 When tight, the bevel adjustment lever should be bottomed

out on the shoe. (Up to .100" off the shoe is acceptable).

28,65 Position the pointer such that the arrow indicates between

the zero and one degree mark on the bevel plate scale.

Loosen front handle screws to adjust pointer.

71 Orient the washer such that the rounded edge is towards

the depth rail.

72 Orient the washer such that the rounded edge is towards

the bevel plate.

See Detail A

Detail

A

1

2

Summary of Contents

Page 1 - SERVICE PARTS LIST

FIG. PART NO. DESCRIPTION OF PART NO. REQ. 1 02-04-0847 Ball Bearing (1) 2 02-04-1850 Ball Bearing (1) 3 02-50-2423 Needle Bearing (

(1 pages)

(1 pages)

(24 pages)

(24 pages)

Comments to this Manuals